| CONTENTS* | *Note on images | |

| 1. INTRODUCTION | ||

| a. Pinarello | ||

| b. Team Sky | ||

| c. Dogma F8 | ||

| d. Bolide TT | ||

| 2. PRELIMINARY DESIGN | ||

| a. Purposes | ||

| b. Aesthetics | ||

| 3. AERODYNAMIC DESIGN | ||

| a. Concave Downtube | ||

| b. "Fork Flap" | ||

| 4. STRUCTURAL DESIGN | ||

| a. Tubing Design | ||

| b. Material's Choice | ||

| 5. PRODUCTION | ||

| a. RP Samples | ||

| b. Samples | ||

| 6. TESTING | ||

| a. Lab Test | ||

| b. Road Test | ||

| 7. RESULTS | ||

| a. Structural Performances | ||

| b. Riding Performance | ||

| c. Integration | ||

| d. Main Features | ||

| 8. TECHNICAL SPECIFICATIONS | ||

| a. Specifications | ||

| b. Geometries | ||

| 9. RACING | ||

| a. UCI Approved | ||

| b. Debut | ||

| Various Videos from the Press and others: | ||

*This site is a transcription of the Whitepaper published by Pinarello in January of 2017. The images are copied directly from the White Paper and were kept to 700pixels wide in the interest of keeping these pages efficient. Because the original was published in PDF format we were able to make most of the images links to much larger pop-up versions.

1. INTRODUCTION

a. Pinarello

Cicli Pinarello SpA is one of the most famous and winning bike manufacturers in the world. Founded in Treviso (Italy) in 1952 by Giovanni (Nani) Pinarello, it produces high end racing bikes. This name, Pinarello, recalls legendary victories of the greatest cyclists of all times. Since 1975, the first victory in the Giro d'Italia with Fausto Bertaglio, Pinarello has won all the most important races in the world, including the Olympics, World Championships and the Tour de France.

Just in the recent past, we celbrated for:

Elia Viviani - gold medal in Omnium, Rio 2016 Olympics

Chris Froome - Winner of the Tour de France 2013, 2015 & 2016 and Vuelte d' Espania 2016

Wout Poels - Winner of Liege-Bastogne-Liege 2016

Vasil Kiryienka - Time Trial World Champion in Richmond 2015

Sir Bradley Wiggins - Hour Record in London 2015 & Time Trial World chapion in Ponferrada 2014.

b. Team Sky

Pinarello has supported Team Sky since its foundation in 2009, providing the team with the best bikes in the business. This collaboration allowed us to test our bikes in the most important races across the world and to gather precious feedback to further improve them.

During these years, we developed 8 road bikes and 3 time trial bikes, which have been successfully used by the team to win numerous races.

Our collaboration is now extended, at least until 2020, and we are already working on some more amazing projects.

c. Dogma F8

The Dogma F8, presented in May of 2014, is one of the most famous and winning bicycles in the world. It is also the best selling frame in Pinarello hisotory, and the most imitated frame on the web, an unquestionable symptom of how it is the absolute benchmark in the cycling world

On-board the Dogma F8, riders of Team Sky have won more than 90 races in the last 3 years. These races include sprint finishes, uphill finishes and breakaway finishes: this highlights the "all-around" character of this fantastic bike.

The Dogma F8 has won innumerable awards, including Best Road Bike of the world, Bicycling Magazine Editors' Choice in 2015 and 2016, and the London Design Award in 2014.

d. Bolide TT

The bolide TT debut at the 9th stage of the 2016 Giro d'Italia, helping Mikel Landa ride an excellent TT stage. A few weeks later, during the Tour de France and the Vuelta a Espana, it helped Chris Froome and Team Sky win three victories and 4 second places....amazing!

The development of the Bolide TT used the Bolide and the Bolide HR as a starting pont, adding some innovative technologies and cutting-edge features, such as the concave down tube along the way.

These concepts and technologies were later adjusted to a road bike to generate the Dogma F10.

2. Preliminary Design

a. Purposes

At the beginning of the project, we established the required design changes, to follow them along the development and, at the end, to verify that the new bike meets our goals.

The main aim of the new bike was to maintain "all-around" characteristics, which means a stiff and light bike, with excellent aerodynamic balance. At the same time we had to maintain the unique "Pinarello" flavor, synonymous with agility and precision in every corner.

In consideration of our goals, the main targets were:

- Maintain the same handling, to guarantee the unique Pinarello flavor for every rider and cyclist. We maintained the geometry of the dogma F8 (13 sizes allowing every rider to find the frame which best accommodates their body), and the same tapered headset (top bearing 1-1/8", bottom bearing 1-1/2");

-Increase stiffness, to avoid any waste of energy and to have a more balanced bike. A further development of the asymmetry concept allowed us to reach this, in combination with new carbon fibre choices;

-Reduce drag, to reduce any waste of energy due to air resistance. We added new, innovative features derived from the development of the Bolide HR and from an in-depth CVD (aerodynamics) analysis, which optimizes airflow along the bike;

-Reduce the weight, to reduce the energy needed in a hilly route or on climbs and to allow quicker accerations and braking. The choice of carbon fibre in combination with the optimization of the tubing sections and the further development of the asymmetry concepts aided us in reaching this goal.

b. Aesthetics

Pinarello bikes are unique because of their mix of performance with aesthetics. All the bikes which we develop and produce are not only winning bikes, they are also beautiful. therefore, during development we took care to combine the features derived by CFD and FEA (for structural performance) with aesthetics.....what results is , simply, a work of art.

You can see below a few sketches used during the developmnet. These sketches , even though perliminary, already demonstrate some important features which were later expanded on such as the elongated fork dropouts, the enlarged transition between the top tube and the seat tube, and the concave down tube.

Aesthetics were, as always, finalized by hand. Using 3D printed samples we could see and touch the shape of each tube and transition; then, using sand paper and apposite tools we smoothed and improved the surfaces. These modifications were then applied to the 3ED drawings in order to obtain a satisfactory final design.

Aerodynamic Design

3. Aerodynamic Design

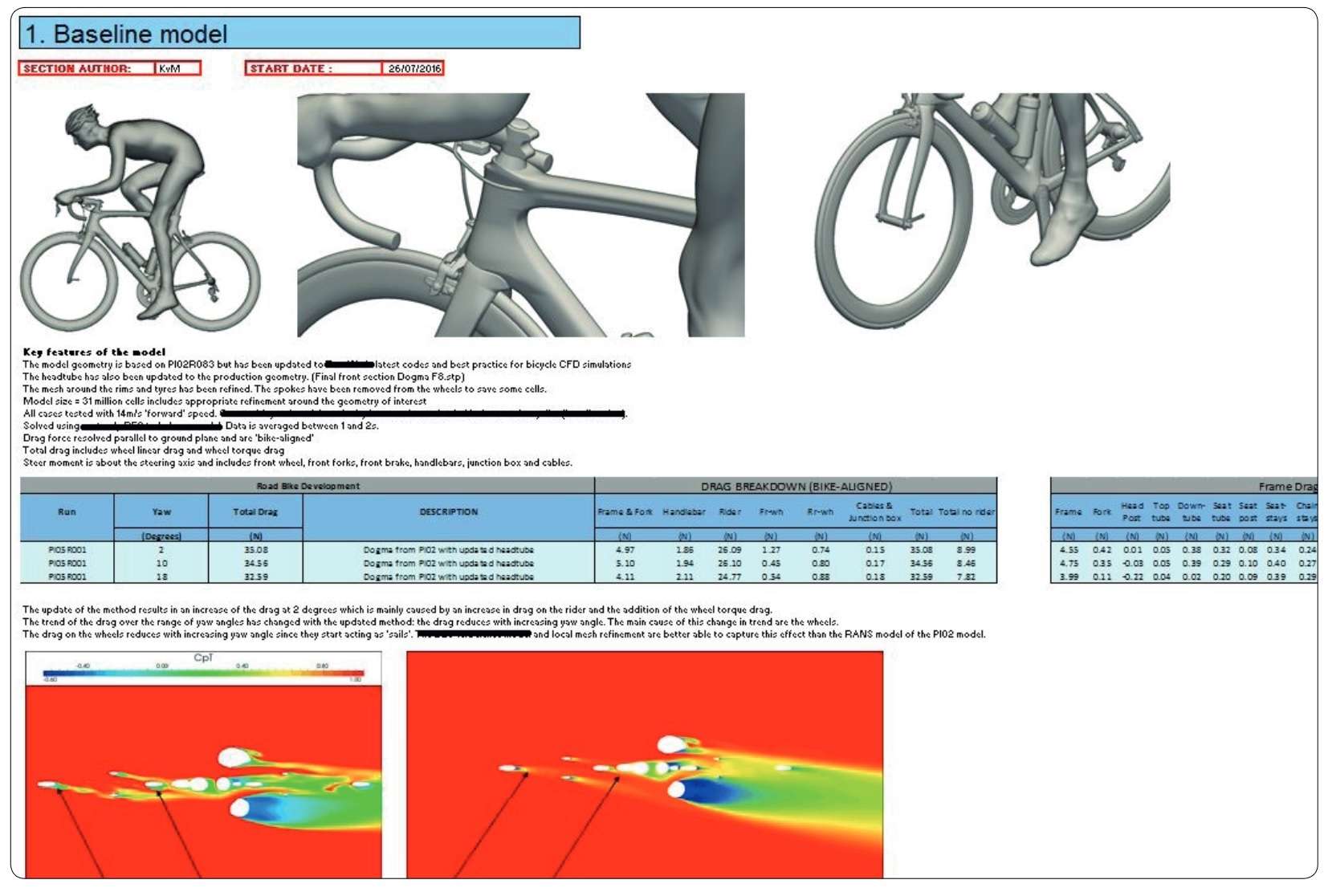

The in-depth aerodynamic analysis and the vast amount of data derived during the development of the Bolide HR and the Bolide TT was applied to optimize the aero performance of the Dogma F10.

Analysis and improvements were focused on reducing the overall drag of the entire bike+rider system. Aerodynamics is a complex area of study due to the interaction between airflow and all the components, not just the frame and fork. The optimization of the parts/components one by one can actually reduce aerodynamic performance for the complete system precisely because it does not take interactions between those parts into account. On the other hand a modification of a component that actually causes an increase in local drag can and often does result in an overall performance iprovement.

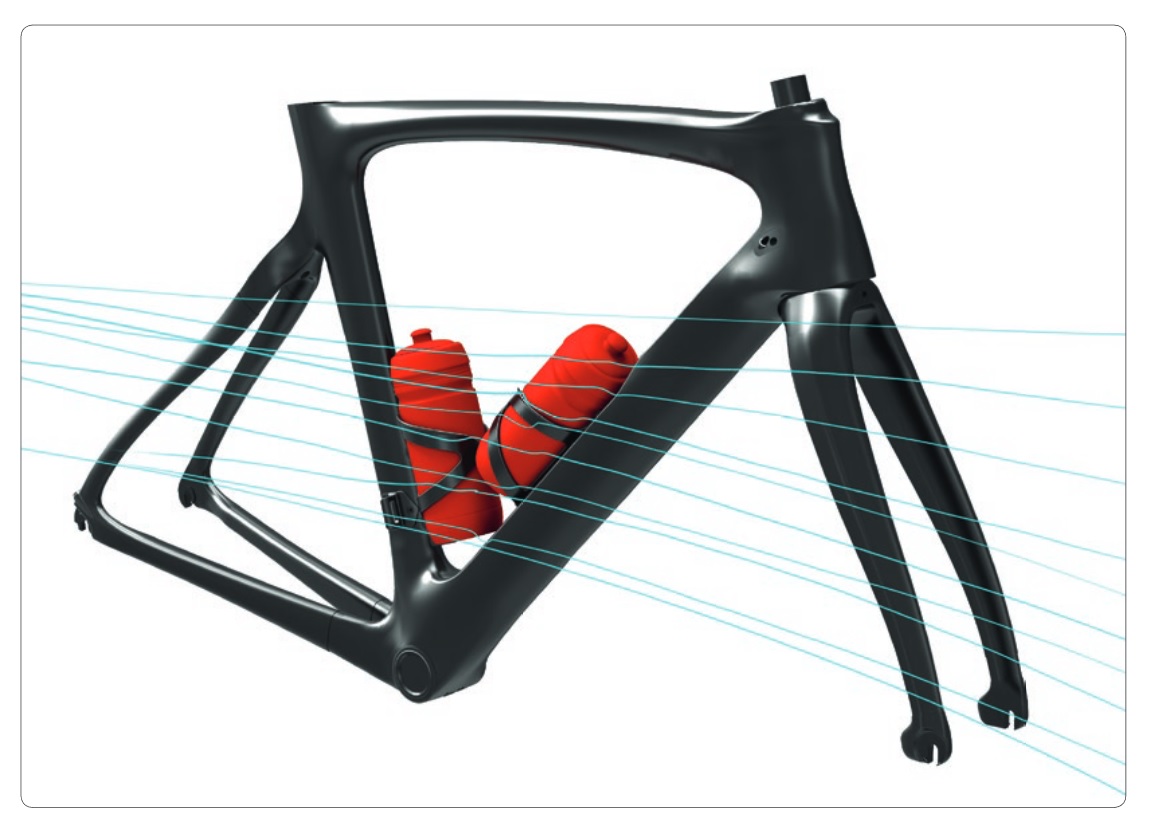

The down tube is on of the major influencers of bicycle frame aerodynamics. Because of it's position just behind the front wheel, and it's dimensions (the most massive tube of the frame), it generates more than 15% of total drag. Intuitively then, the reduction of drag caused by the down tube will have a significant influence on reducing overall drag. Because of the complexity of the aerodynamic interactions between the down tube, frame, wheels and rider it is especially difficult to design.

The down tube is placed in front of the the water bottles and the seat tube and, in effect, protects them from airflow. It was thought that even a small redesign of the down tube would lead to an increase in overall drag. What we found was that by expanding the focus of our research on a drathe interaction of the down tube and water bottles we were able to achieve a significant overall performance improvement.

We developed several possible down tube cross sections in order to optimize this interaction. CFD analysis allowed us to compare these many options.

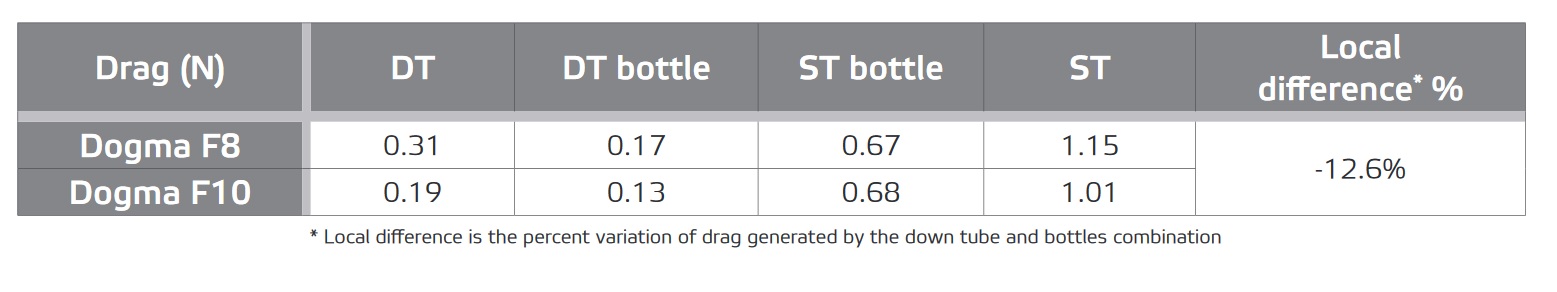

The chard below is an extract of the results when we compared the Dogma F8 with the Dogma f10:

The final design of the down tube lead to extraordinary results: drag of the tube alitself was reduced while, at the same time, reducing system drag. The final result was an overall reduction of 12.6%

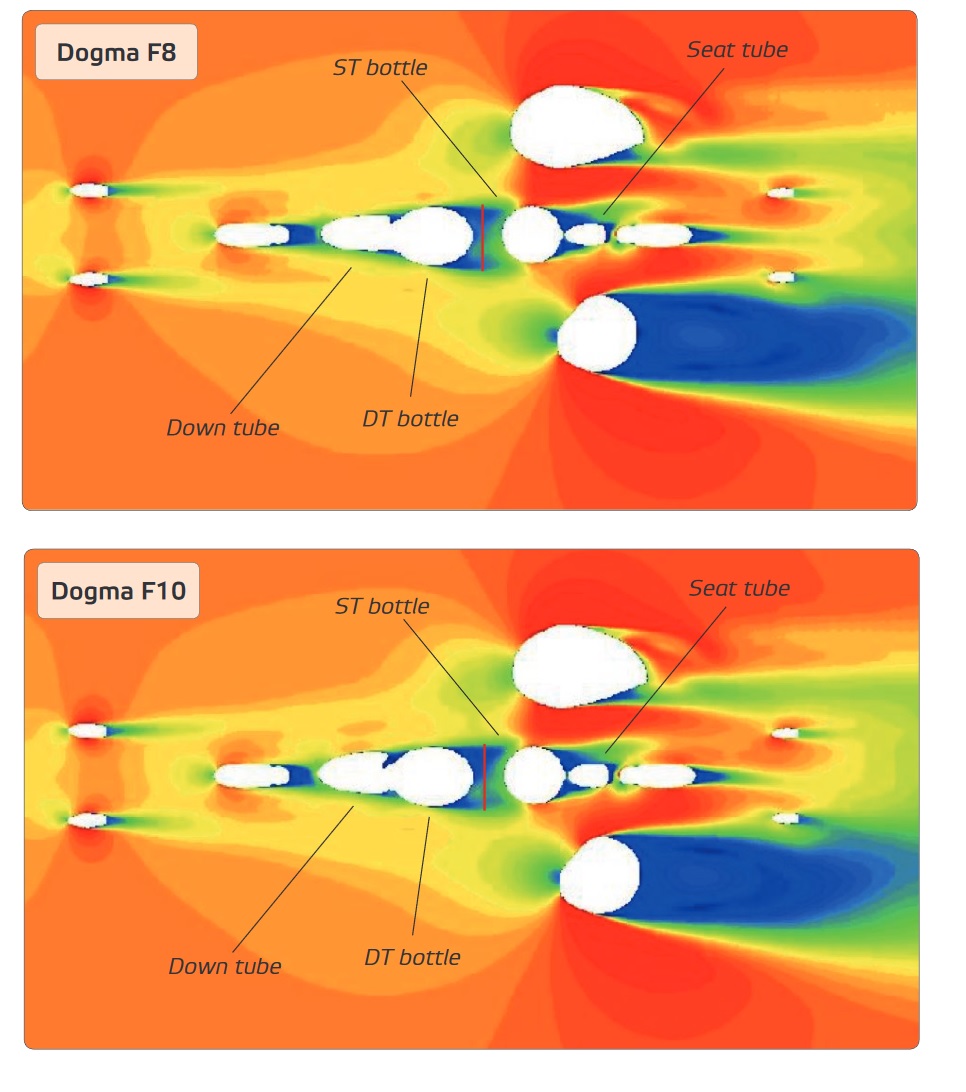

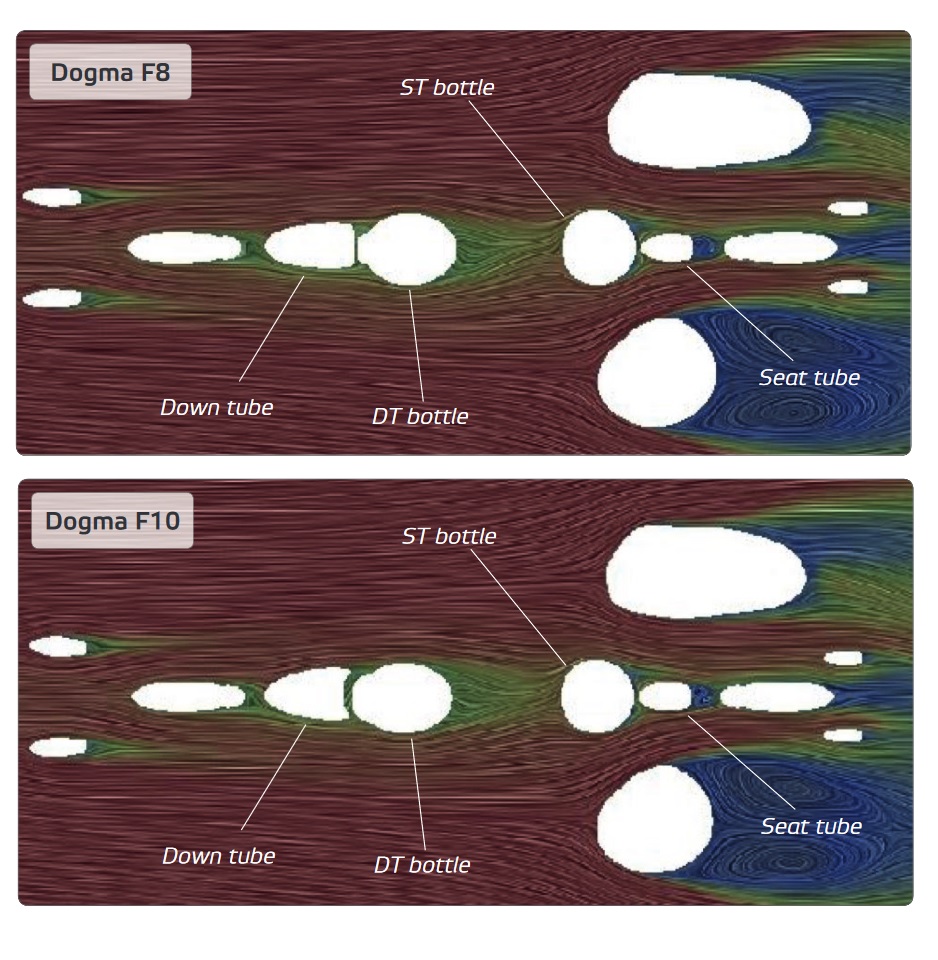

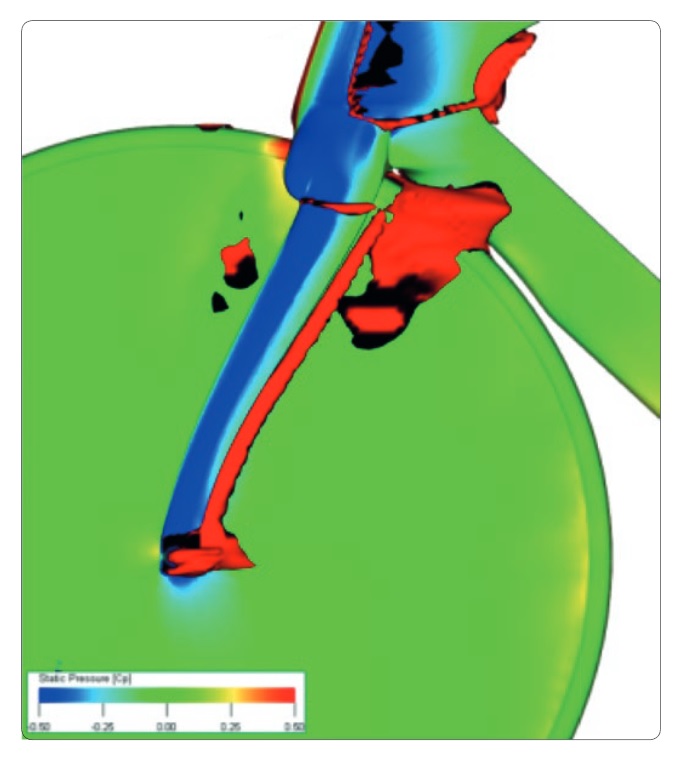

The images below compare the airflow between the Dogma F8 and the Dogma F10. Blue indicates low pressure areas and it can be readily seen that the Dogma F10 bennefits from a small but significan reduction in the low pressure area. This effect, multiplied by the length of the area was what gave us our improvement.

The next images show how he air flows along the bike. The transition of airflow between the down tube and the bottle is smoother on the Dogma F10 due to the down tube partially sheilding the bottle

The front of the bike is it's the most imortant aerodynamic element because it is the first part which interacts with airflow and influences everything behind. Even a small aerodynamic improvements in this area are crucial.

On road bikes the wheels are finfixed using quick release skewers. The quick release consists of a rod threaded on one end with a lever operated cam assembly on the other. This mechansim allows quick wheel changes but, in terms of aerodynamics, is sub optimal. The nut end and, especially, the lever are quite bulky and have a disproportionate impact on overall aerodynamic performance.

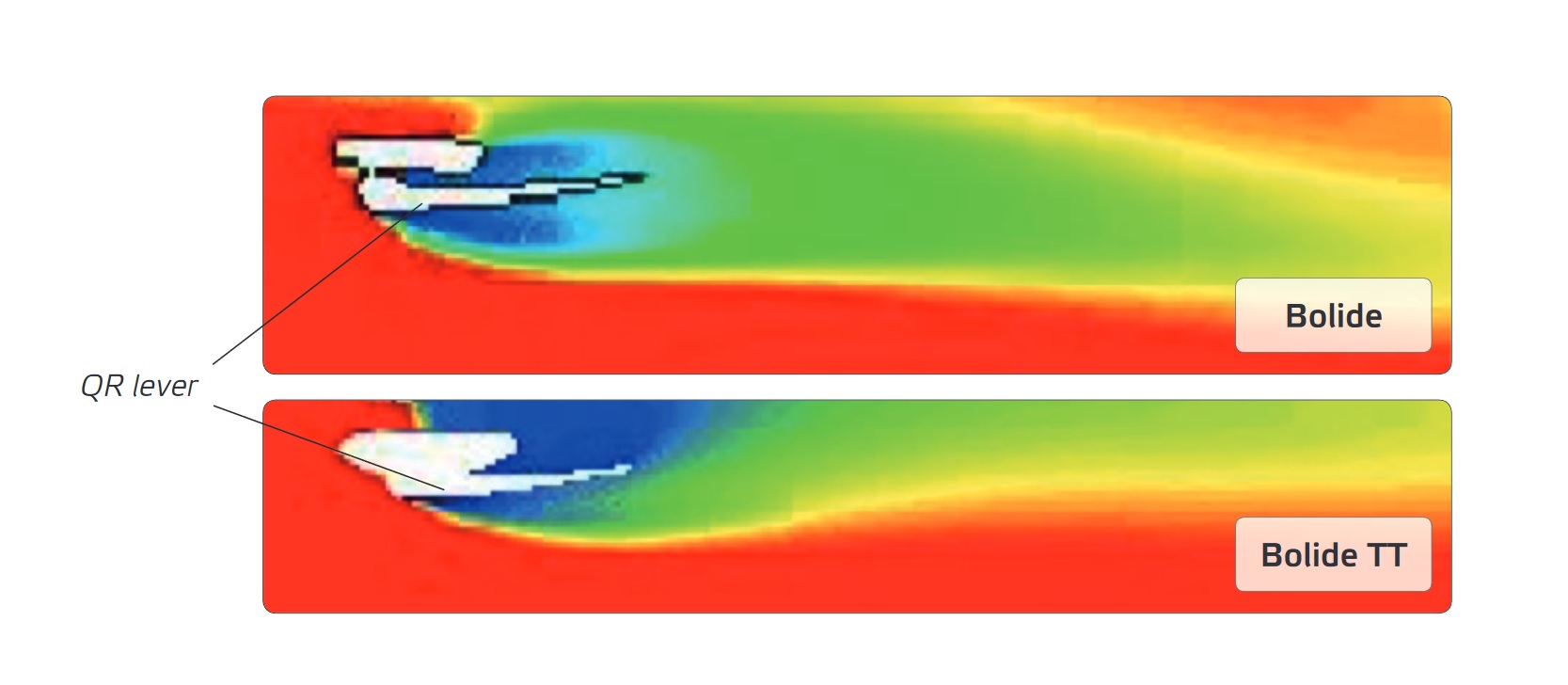

We determined that it might be possible to mitigate aerodynamic the effects of skewers by modifying the dropouts. an in-depth analysis of this was performed during the development of the Bolide HR. The CFD image below shows the drag gnerated bhend the fork of the is quite small:

The presence of the quick release lever generates a large low pressure area. Modifying the shape of the dropout by adding material to form a faring where the low pressure area was large, we were able to reduce it and measurably decrease overall drag. This small modification has lead to a drag reduction at the fork of up to 10%.

IThe images above show the comparison between theslipstream generated by the left dropout lever on the Bolide and the Bolide TT. Because of the design of the dropout which encloses part of the lever, the low pressure area is narrower and, especially, tends to move towards the frame. In the Bolide, the low preassure area moves awawy from the frame.Even though the local low preassure area is larger, the overall effect was to reduce final drag.

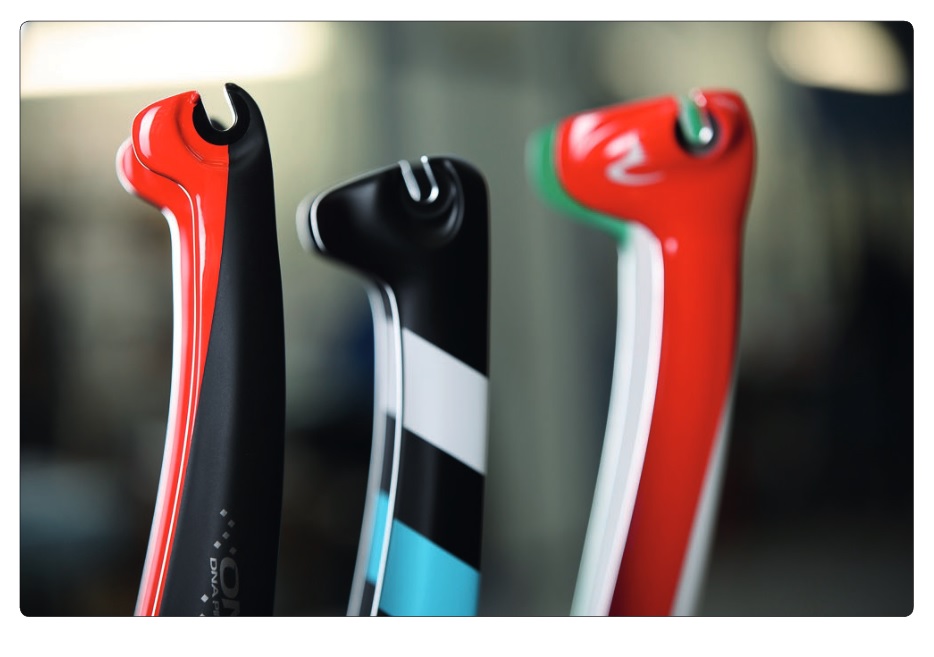

On the Bolide HR we further reduced drag by integrating the wheel fixing nuts. We later used this technique while developing the Bolide TT but eventually returned to commercial quick releases . On the Dogma F10 we used the same faring concept from the Bolide TT, taking into account the forks weight. The final design is a compromise between optimal aerodynamics and low weight. The picture below shows, from left to right, the dropouts from the Dogma F10, the Bolide TT and the Bolide HR.

4. Structural Design

a. Tubin Design

Cross sections and the overall shape of tubes as much as the materials choice are critically important to ensure stiffness, lightness and ride. At the same time, as discussed above, it has a deep influence on aerodynamics. The final design of the tubes determines if there is an optimal compromise between these design parameters.

Since 2009 Pinarello has studied and developed the asymmetry concept. At first it mounds rather strange, but the logic behind it is compelling. A "normal" frame is symmetric from right to left. Although this may sound logical, in fact it completely ignores the crucial fact that the transmission (chain set, chain and gears) are on the right side. When the rider is pushing the pedals, the majority of the forces from tension on the chain are acting only n the right side of the bike. A correct design should take this fundamental asymmetry into account and result in an asymmetric frame. A symmetric frame will cause a reduction in the frame's stiffness and and unpleasant feeling ride, especially under high stress while sprinting or climbing etc. The asymmetric design of Pinarello frames (the right side of the frame and fork tubes are larger than the left) optimally counteracts the asymmetric forces and provides a stiffer and more balanced bike.

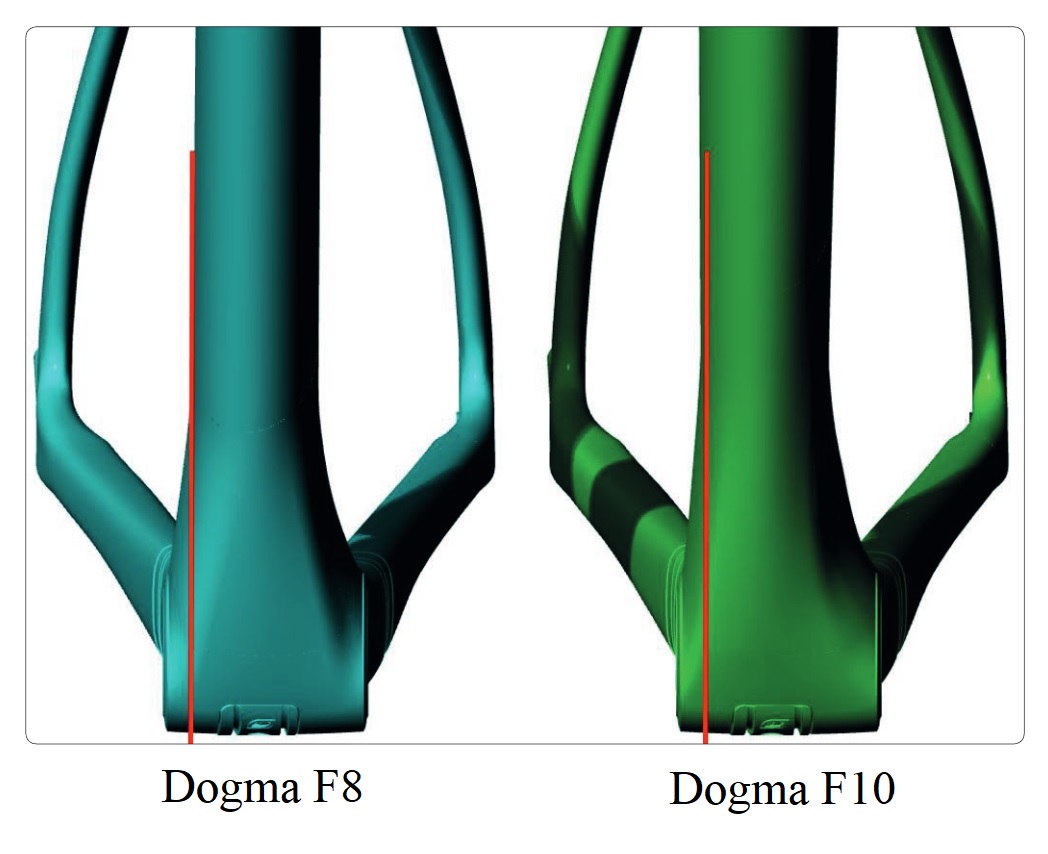

In 2013, while developing the Dogma F8 in collaboration with FEM, we revolutionized this concept. Tubes were not only enlarged but also shifted to the right side of the frame. The result was an amazing 12% increase in stiffness and a 16% increase in the balance of the frame.

In developing the Dogma F10 we further expanded on this asymmetry of the frame, moving the tubes even more toward the right side of the frame. This new design further improved the overall performance of the bike, especially in terms of stiffness.

Below you can see the comparison between the down tubes of the Dogma F8 (left) and the Dogma F10 (right) near the BB. The red line is positioned at the same distance from the center of the bike in both pictures and highlights that the down tube of the Dogma F10 has been moved further toward the right. This relatively small difference has measurably improved the performance of the frame

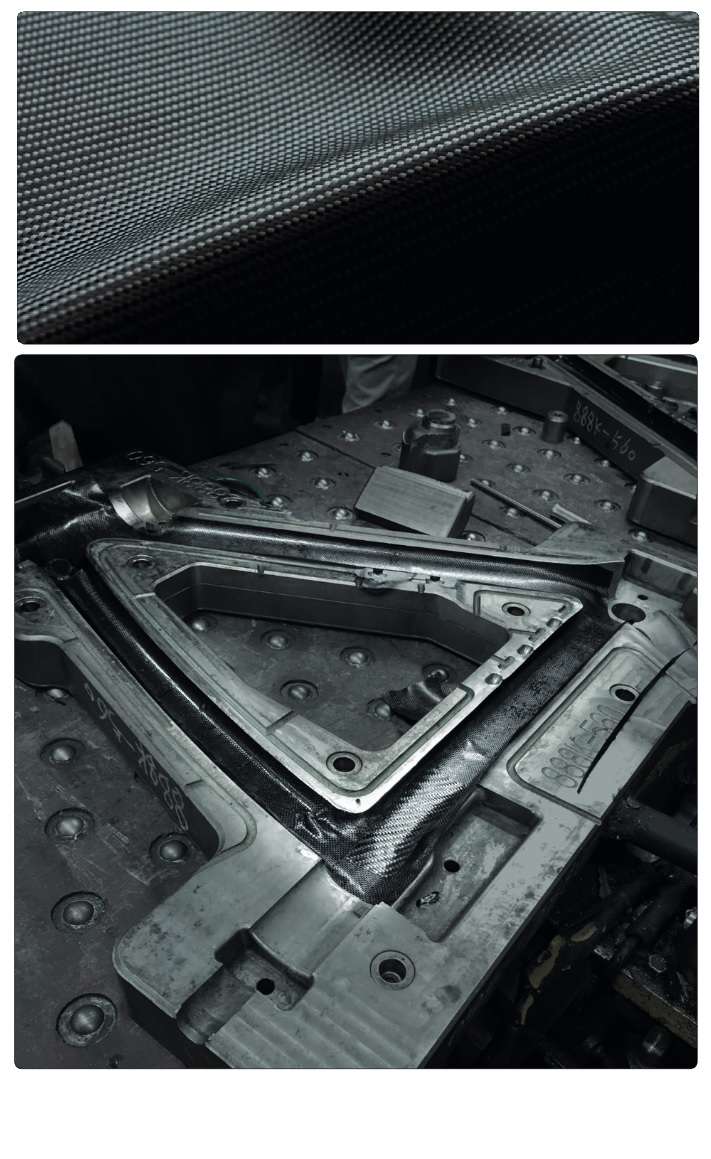

b. Materials's Choice

The proper choice of materials deeply influences the performance of the frame. Carbon Fibre Reinforced Polymer (CFRP) in particular can be optimized for every area of the frame to achieve the optimal combination of stiffness and light weight. Carbon fibre (more properly "composite materials") are a mixture of various types of carbon fibre and resin and it's ultimate properties depend on the synergistic properties of the carbon fibres, resin, lay-up and other production methods. Changing any of these properties will have often profound effects on the final outcome.

Traditional metals, steel, aluminum or titanium, are isotropic materials, their properties are uniform in all directions. This results in predictable and often satisfactory average properties but does not allow the designer the option of optimization at each stress point. Composite materials, on the other hand, can be orthotropic materials, they have properties that very along three mutually orthogonal dual axes of rotational symmetry. The materials properties change depending on the direction at which stress is applied so that the material can be optimized to allow for local stresses

For example: The down tube of the frame is primarily subjected to torsion and lateral flection. The effect of these stresses is very burdensome to the down tube, which should be reinforced to resist them. In the past the down tube was a circular tube made of steel which is an adequately stiff material capable of counteracting those stresses. When the industry moved to aluminum, which results in a lighter frame but is less stiff than steel, the shape of down tubes became elliptical with the longer dimension transverse to the frame. This increased the inertial moment of the tube which compensated for the properties of the new material. Today DFRP can be draped in the optimal direction to counteract stresses, thus allowing the possibility of a highly aero cross-section without loss of stiffness.

A second advantage of composite materials is the use of different types and grades of carbon fibre and/or resin based on local stresses. In areas where stiffness is important, a high modulus fibre (HM) can be used, while where strength is the primary concern a high strength fibre (HT) can be selected. This variation of materials can be done locally in the same frame, while a frame made of a metallic material is denied this option.

On the Dogma F10 the main material is Torayca T1100 1K which ensures the highest tensile strength currently available. this choice contributes to the impact strength of the frame making breakage in response to an insult less likely.

The improvement of asymmetry, with the down tube moved further to the right, allowed us to increase the stiffness by careful selection of shape while using less material allowing us to keep weight at a minimum.

Thanks to the highest grade of carbon fibre we were able to get a lighter frame while maintaining it's strength. T1100 fibers have been used in the higher stress areas in order to take advantage of it's incomparable strength.

5. PRODUCTION

a. RP Samples

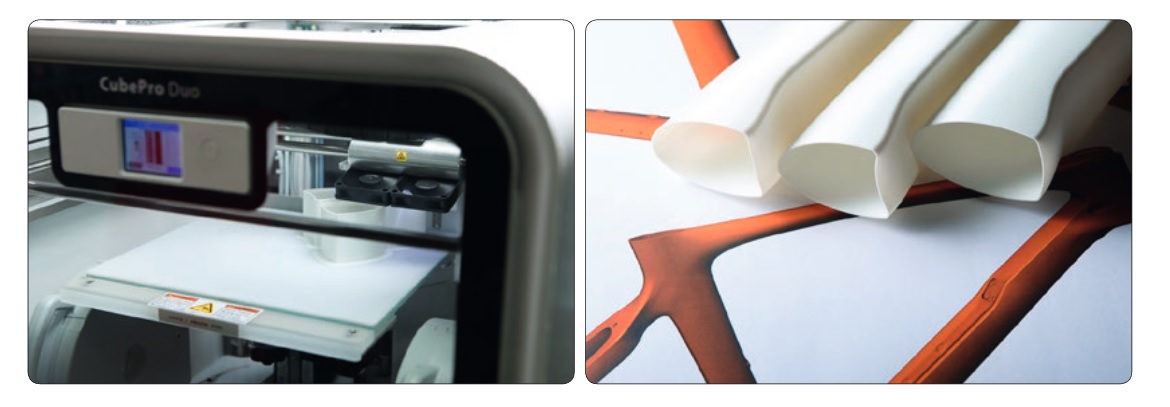

During the development of the Dogma F10 we made extensive use of 3D printing which gave us real time access to physical prototypes. By using an in-house 3D printer we had ready access to numerous samples of each part of the frame and were able to verify aesaesthetics and fit. For example in the picture below we were able to simultaneously compare several prototype tubes with out the often lengthy waits we traditionally faced with conventional design procedures.

We also printed RP samples of entire frame prototypes for aesthetic and design optimization prior to the expensive process of building actual molds.

b. Carbon Samples

Once we finished with the main design and developmnet we proceeded with production of carbon prototypes. These were used first, to verify that completly assembled frames satisfyed our aesthetic and performance goals. With these prototypes available we were able to perform static and fatigue tests and to measure the stiffness of the completed frame against our target goals.

6. TESTING

a. Lab Tests

b. Road Tests

We also performed multiple road tests to verify the real world behavior of the Dogma F10. These tests also offered useful feedback from various levels of riders from enthusiastic armatures to world class professionals to further improve the final product. Chris Froome was the first rider to test the new Dogma F10. His initial comment was "Great work guys!", very encouraging feedback from arguably the greatest road rider today.

7. RESULTS

a. Structural Performance

Once the design phase was finished we produced samples to test performance of the frame against our initial specifications.

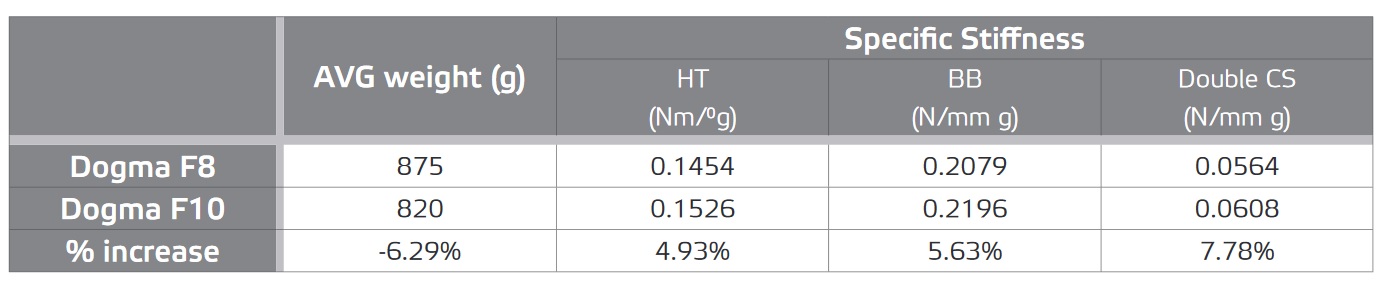

We performed fatigue and crash tests on several frames to verify strength and safety. We also measured the mechanical performance (stiffness and weight) against a 53cm Dogma F8.

What is clearly evident from this chard is a 6.3% reduction in weight to 820 g in the 53cm Dogma F10. All values of stiffness were higher than the for the Dogma F8. Comparing the stiffness of two frames without considering the effect of weight can produce misleading results: generally the more material used the stiffer the frame....but also the heavier. To counteract this we measured Specific Stiffness, the value of the stiffness divided by the weight. The specific stiffness of the Dogma F10 is 7% higher than the Dogma F8.

In short: The Dogma F10 is 6.3% lighter and 7% stiffer than the Dogma F8. We are very pleased.

b. Riding Performance

The numbers above are extraordinary, particularly as they are in comparison to the Dogma F8, but at the same time they are quite technicle and do not speak well to ride feel. What a rider commonly perceives is the reactivity and handling of a bike; frame, fork and wheels are the main players in this game.

Reactivity, the frames quickness in transferring pressure on the pedals into acceleration, turns out to be one of the major performance features noticed by the rider. this characteristic depends primarily on 2 factors: weight and stiffness. The lower weight of the Dogma F10 ensures quicker accelerations and decelerations. The higher stiffness, especially of the down tube/bottom bracket and chain stays, results in better power transfer without power loss due to deformation of the frame. All the power generated by the rider's legs goes directly to the rear wheel, where it belongs.

Handling is the capability to change direction quickly and predictably and mainly depends on the geometry (head tube angle, fork rake, wheelbase, etc.) and the frontal stiffness of the frame.

The Dogma F10 shares the identical geometry with the Dogma F8, which was judged by riders as among the most precise and responsive in the world even before the Dogma F10's increases in head tube and fork stiffness.

These theoretical improvements have been repeatedly confirmed by real riders. We believe that it is now time for you to test and enjoy your own Pinarello super bike.

c. Integration

Integration of all the parts ensures the optimal bicycle performance. In particular:

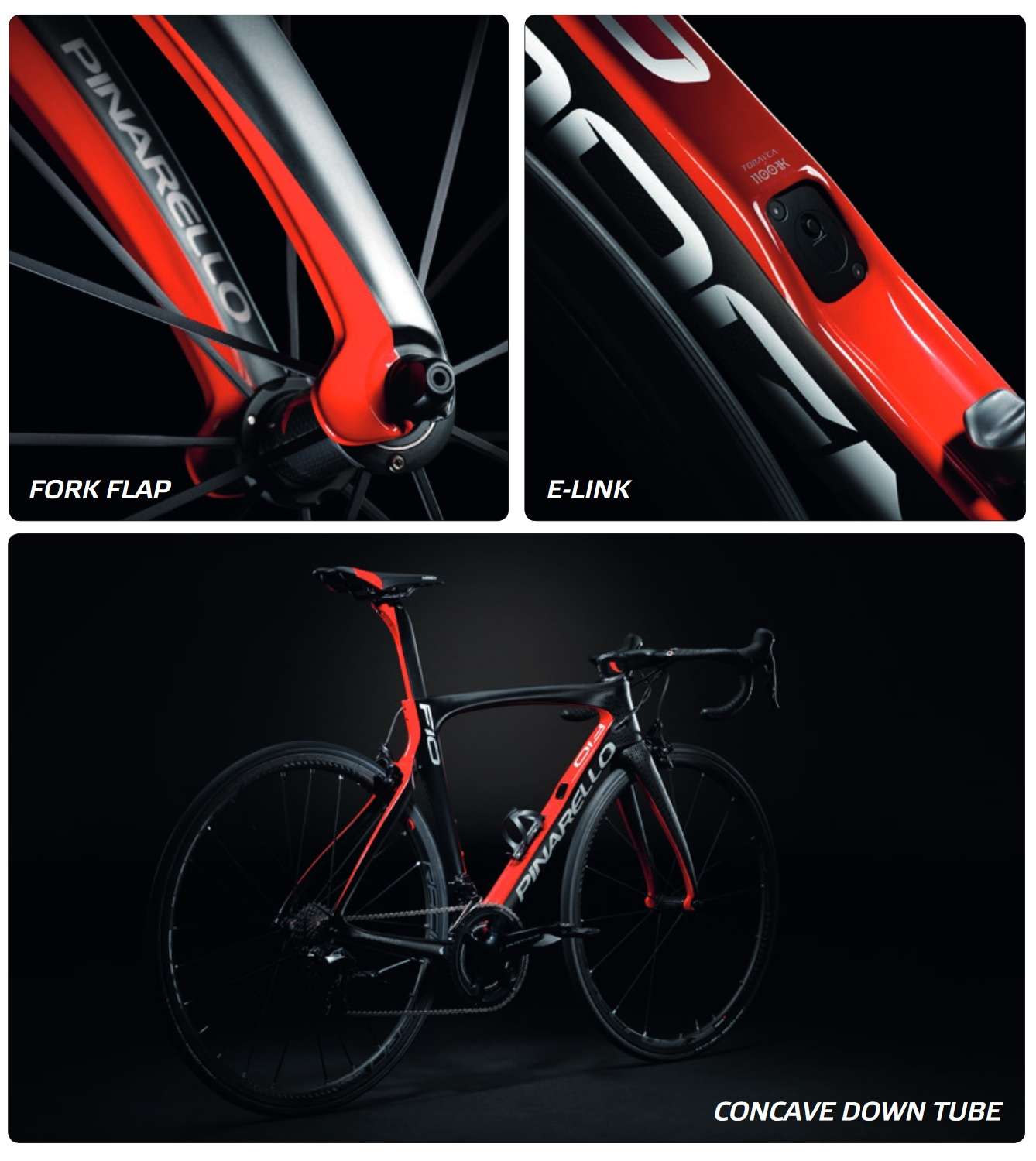

E-Link: the junction of for Shimano's new DuraAce Di2 (EW-RS910) will be integrated into the down tube and easily accessible for adjustment and recharge;

Internal cable routing: housings and electronic cables pass internally through the frame for better aerodynamics and aesthetics;

Think2 technology: the frame is compatible with both mechanical and electronic group sets;

Internal battery: the battery is fixed inside the frame for better aerodynamics and aesthetics;

Integrated seatclamp: the Twin Force seatclamp is integrated into the frame ensuring low aero drag and firm clamping of the seatpost.

d. Main Features

The incomparable performance of the Dogma F10 depends heavily on the innovative features developed into it. The most significant of which are: "Fork Flap", E-Link, and The Concave Down Tube.

Technical Specifications

8. Technical Specifications

a. Specifications

With the introduction of the Dogma F10 Pinarello continues and extends their tradition of technological leadership:

| Dogma F10 Innovations: |

| E-Link |

| Fork Flap |

| Concave Down Tube |

| Torayca T1100 1K Carbon |

| Asymmetric Frame |

| Italian Bottom Bracket |

| Tapered 1-1/8" (Upper) to 1-1/2" (lower) Headset |

| Think2 Technology |

| Internal Cable Routing |

| Internal Battery Mount |

| Twin Force Seat Clamp Closure |

| 3 X Air |

| Flat Back Profile |

| 25mm Tire Compatibility |

| 820g (raw frame in 53cm size) |

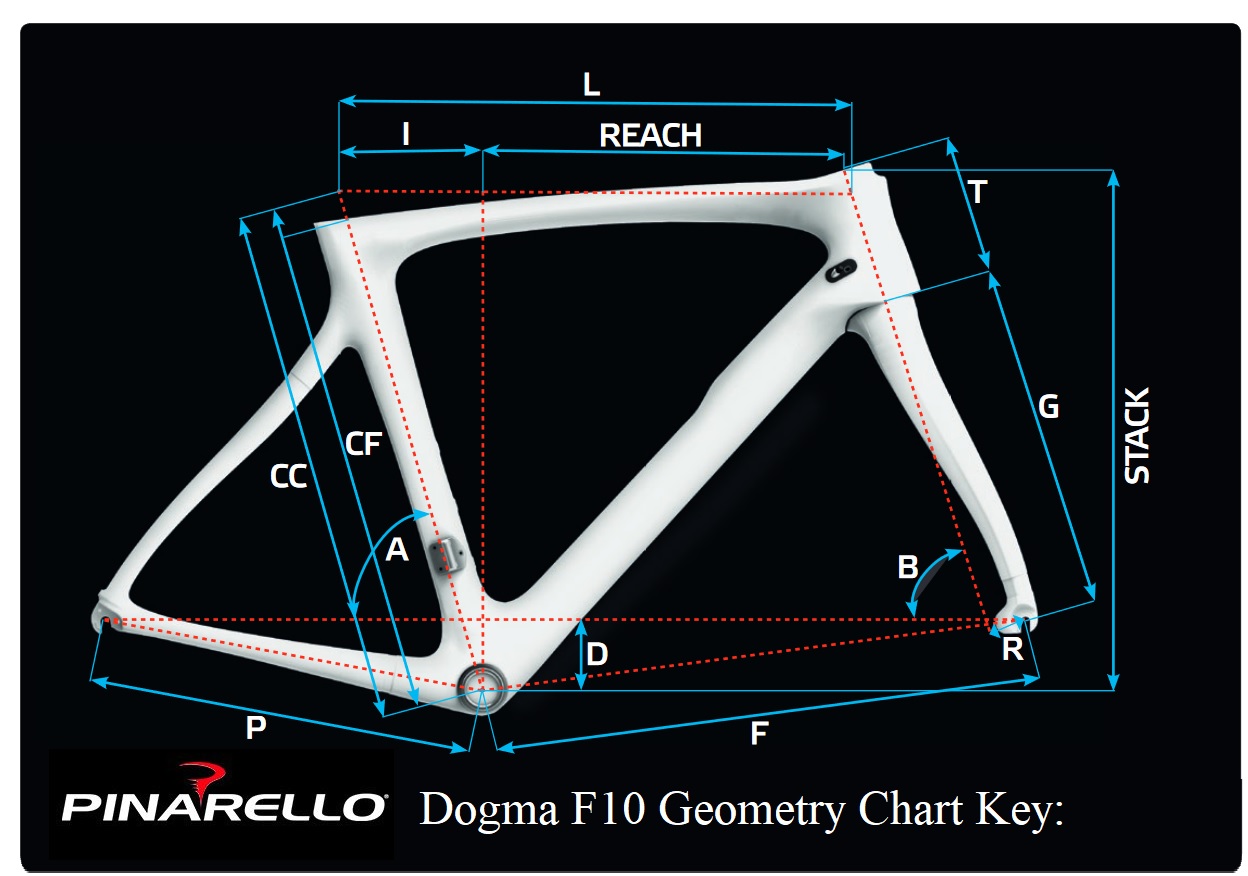

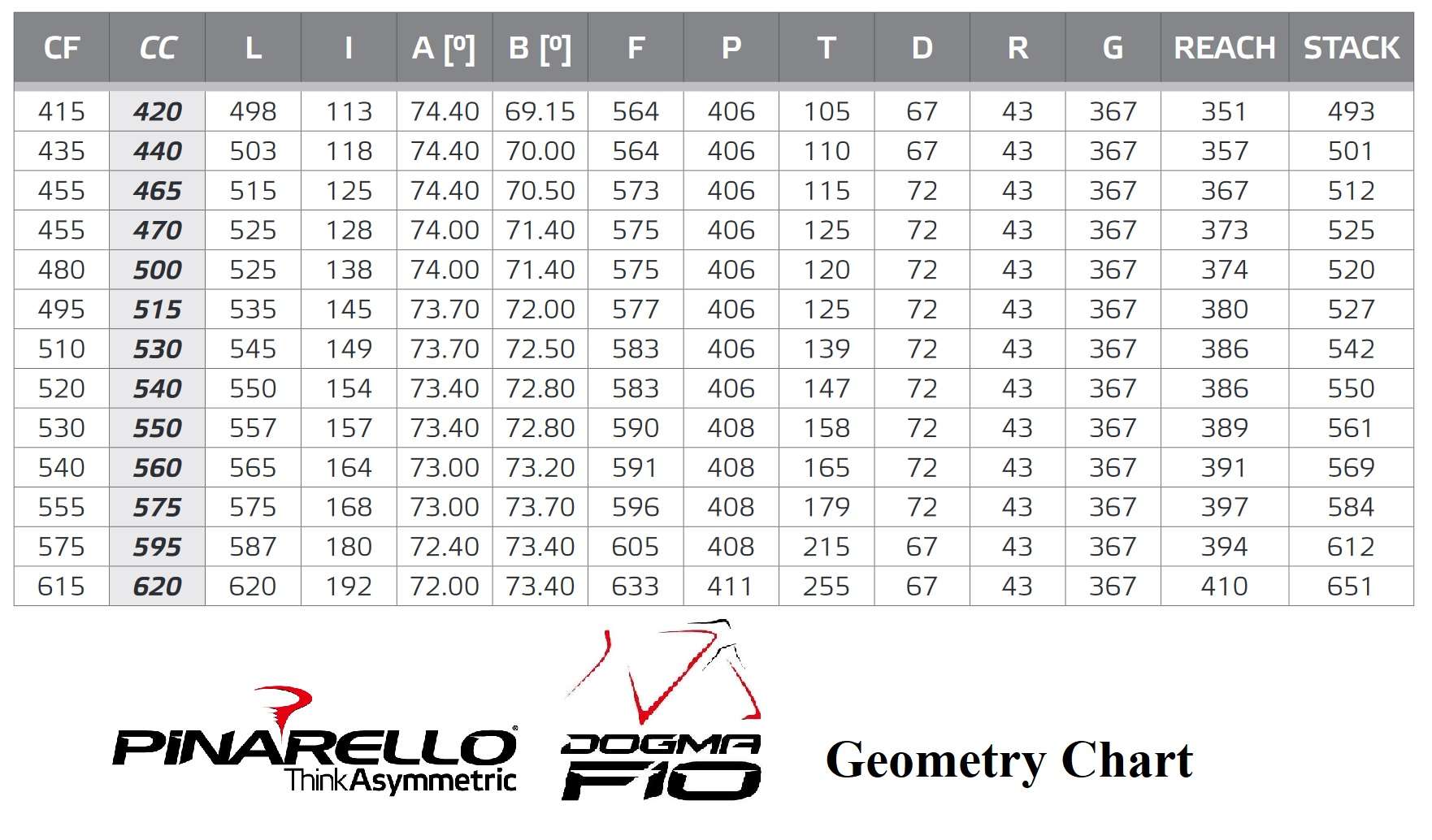

b. Geometry

Pinarello is accustomed to offering every single rider the best possible bicycle. In aid of this we offer the Dogma F10 in 13 unique sizes to allow every rider to find the one that best suits their body. Everyone of these sizes is designed and produced individually: Larger sizes are reinforced and shaped in order to better manage the higher stresses imposed by larger riders while the smaller sizes are manufactured using less material thus both saving weight and resulting in a smoother ride for lighter, smaller riders.